Architecture in motion

MIKALON bike – Titanium mini sprinter

We didn’t start as a bicycle company.

Designed and fabricated by Il Hoon Roh, a UK-chartered architect and former architect at Norman Foster’s office, MIKALON is rooted in architecture, sculpture, and structural research. Roh has spent years exploring structural efficiency inspired by nature—work that has entered major public and private collections, including the permanent collection of the Centre Pompidou in Paris and the Thierry Barbier-Mueller Collection in Switzerland.

Initiated in 2018, the MIKALON project translates over a decade of structural research into a single, resolved object. The bicycle was selected as its medium, as its performance is determined directly by structural efficiency.

MIKALON is a response to the limitations of traditional exhibition formats. Instead of a static object confined to a gallery, it is conceived as a nomadic artwork—designed to be used, experienced, and integrated into everyday life: an exhibition that never ends. It is not a product that aspires to become art, but an artwork that takes the form of a bicycle.

Why separable?

Most folding bicycles are designed by first selecting a folding mechanism, with the frame subsequently adapted to accommodate it. This approach can influence structural layout, stiffness, and overall visual proportions.

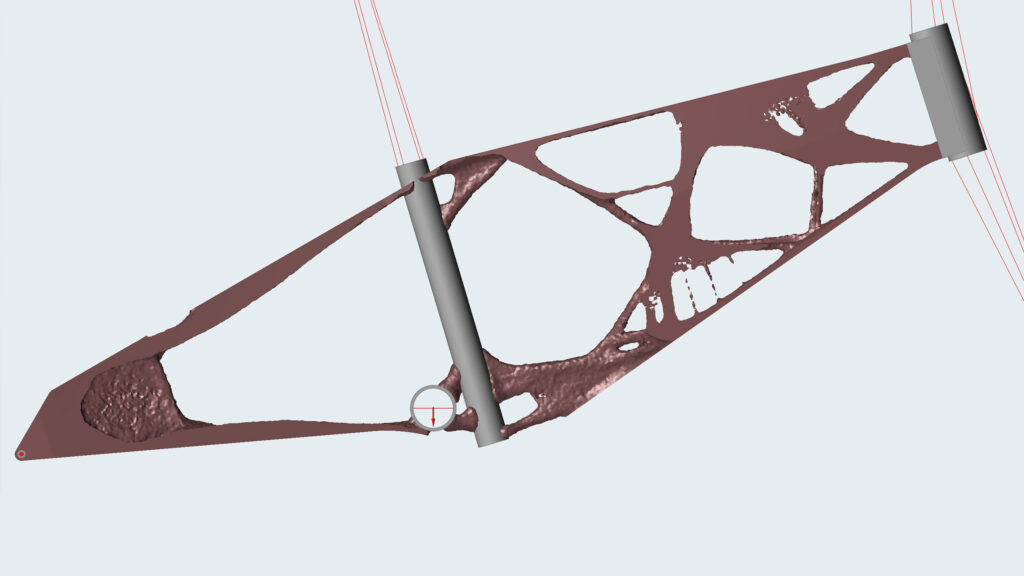

MIKALON adopts a different design sequence. The frame was developed with an initial focus on achieving an efficient balance of weight, strength, and structural clarity. A hybrid folding system incorporating a separable mechanism was introduced afterward, enabling the bicycle to be folded quickly while maintaining the fundamental characteristics of the original frame design.

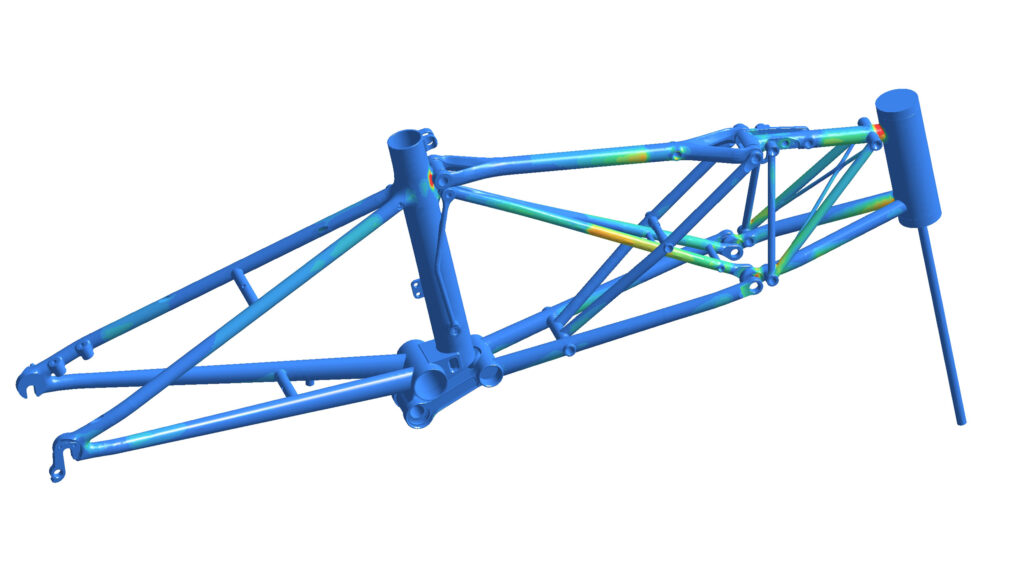

By treating folding as a secondary function, MIKALON aims to preserve ride quality and structural performance while improving portability and compactness. The frame was developed using Altair’s engineering simulation tools, SimSolid and Inspire, to support informed decisions regarding geometry and material distribution.

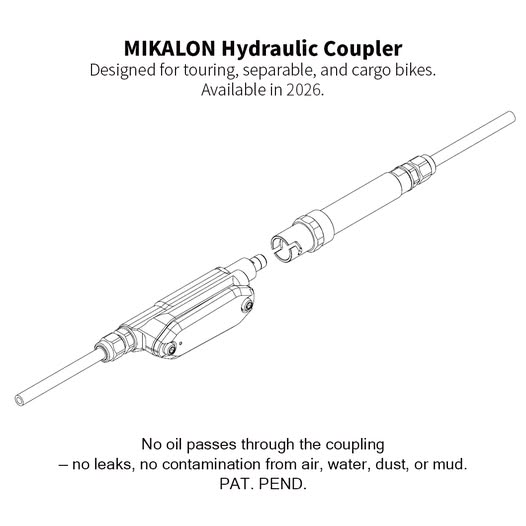

Patented features—including a hydraulic cable separation device, an oil-leak-resistant hydraulic coupler, a height-set retractable stem, and the folding mechanism—further enhance both usability and structural refinement.

Patented retractable stem. (Automatically returns back to the user height setting)

Patent Pending hydraulic cable separation device (separate and reconnect in seconds)

Launching as a standalone product in 2026, our hydraulic coupler is designed for use in touring bikes, separable bikes, cargo bikes, and other systems where hydraulic line disconnection is required.

Performance may vary depending on installation, use conditions, and maintenance.

Titanium frames were welded in an argon chamber

Designed and manufactured in-house

MIKALON’s unconventional structural approach required a level of control not readily available through conventional bicycle manufacturing. To preserve design intent and quality, all tools and jigs were developed specifically for the project, allowing the frame to be manufactured entirely in-house.

The design was refined through extensive virtual structural simulations and produced in titanium. Critical components are welded in an argon-controlled chamber to support precision and durability. The resulting frame has been tested and confirmed to comply with ISO 4210 (Racing) requirements.

MIKALON reflects an architect’s pursuit of structural clarity and technical precision

ISO 4210 (Racing) Safety requirements for bicycles test

MIKALON bike project was sponsored by Hyosung Advanced Materials & Altair